Hubbell Wiring Device-Kellems

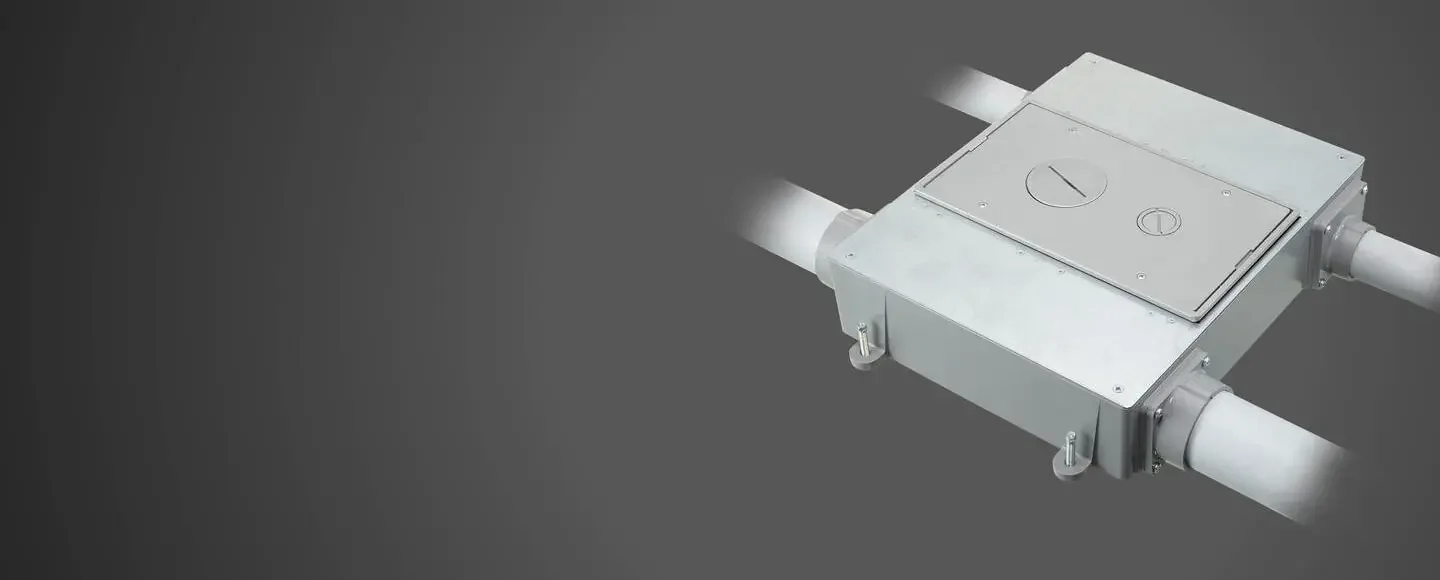

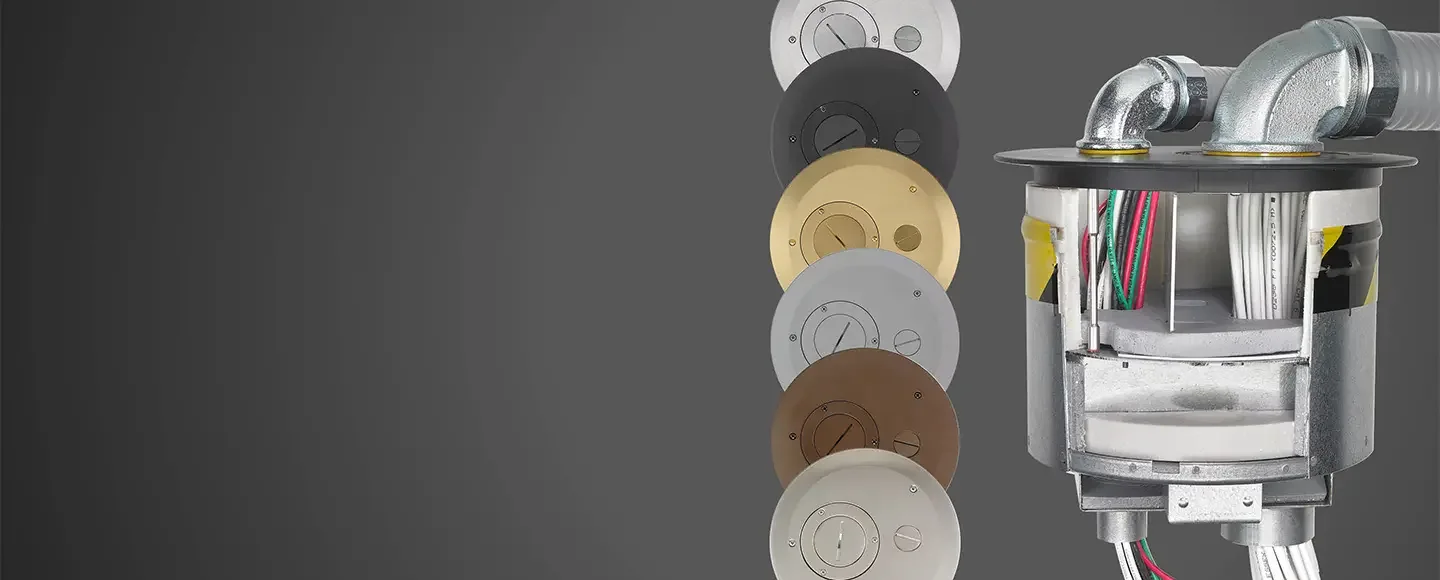

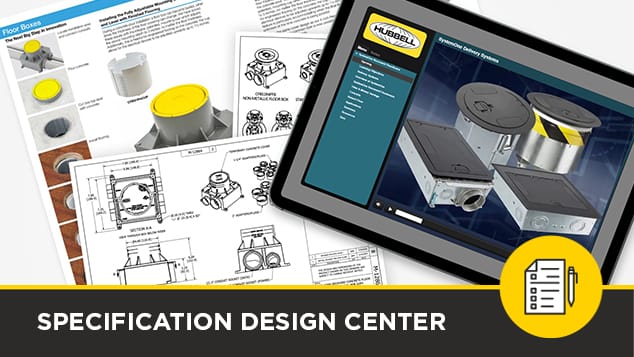

Hubbell Wiring Device-Kellems is the premier manufacturer for products including receptacles and switches, plugs &connectors, Kellems grips &cord connectors, floor boxes &poke-throughs, and more. For more than a century, we’ve listened to what installers, contractors, and end-users want – designing devices that address their biggest challenges. And that forward-thinking approach holds true to everything Hubbell Wiring Device-Kellems does today.

Featured Products

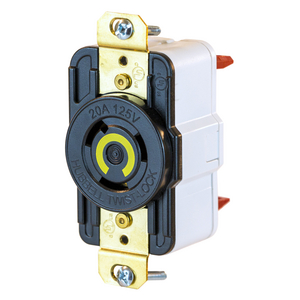

Twist-Lock® Edge Series

Improve installation time by over 80% with screwless terminations

USB-C® PD Receptacles

Charge laptops and devices faster with Power Delivery USB, up to 55W